The steel industry is often considered rigid and traditional, but Germantown Iron & Steel is reshaping the narrative. Located just outside Milwaukee, this forward-thinking company has been mastering the art of steel fabrication since 1968. From humble beginnings, Germantown has transformed into a 53,000-square-foot state-of-the-art facility in Jackson, Wisconsin, where cutting-edge technology meets time-honored craftsmanship.

Specializing in design-build services for both structural and miscellaneous metalwork, Germantown Iron & Steel sets itself apart by blending advanced automation with a deep commitment to quality and relationships. While other companies might compromise quality for speed or cost, Germantown achieves both, thanks to its integration of AI and automation, streamlining processes and enhancing productivity without sacrificing integrity.

Germantown Iron & Steel was founded in the 1960s by the Grutbrod family. What started as a small operation in a garage has evolved into a major player in the steel fabrication industry. The original owner, determined to build something from the ground up, passed on the business to his two sons, who continued to expand the company incrementally over the years. As the business grew, they moved from facility to facility, each larger than the last, meeting the increasing demand for their services. The father remained involved in the company until his passing just a few years ago. At that point the family decided to explore selling the business, seeking a buyer with the drive to grow the company further. Seeing potential in its reputation and untapped opportunities, current owner David Armstrong stepped in, purchasing the business with a vision to take Germantown to the next level.

Under Armstrong’s leadership, the company has embraced innovation and modernized its operations, focusing on company culture, automation, financial metrics, advanced technology, and investing in AISC (American Institute of Steel Construction) and “green” certifications. This transformation has allowed Germantown to compete on a larger scale, pursuing more professional and more sophisticated customers and projects.

At the core of Germantown Iron & Steel’s success is a team of dedicated professionals who embody the company’s values and vision. With a workforce of about 45 members, Germantown places a strong emphasis on hiring for attitude over aptitude. “We can always train people with the drive and dedication to succeed because we do have that depth of skill and knowledge within our existing team,” says Armstrong. This approach reflects Germantown’s belief that skills can be developed, but a positive, team-oriented mindset is crucial for long-term success.

“We can always train people with the drive and dedication to succeed because we do have that depth of skill and knowledge within our existing team.”

David’s leadership is built on the philosophy of surrounding himself with people who know more about the industry than he does. From individuals with decades of experience in structural steel to those who focus solely on best practices, the Germantown team is carefully assembled to ensure the highest standards of quality and efficiency. Armstrong believes in creating a culture where every employee feels like part of the “A-Team,” a tight-knit group that shares the company’s core values.

To reinforce these values, Germantown implements regular training programs, and employees are evaluated not only on their performance but also on how well they embody the company’s mission. In return, employees also provide feedback, grading management on the same core values. This two-way evaluation fosters a strong sense of accountability and mutual respect within the team, fostering an environment where growth and innovation thrive.

Central to Germantown’s success is its unwavering commitment to these core values, which guide the company’s culture and operations. To support this, Germantown has adopted the Entrepreneurial Operating System (EOS), a management framework developed by Gino Wickman that helps businesses align their vision and processes for growth. EOS emphasizes clarity, accountability, and effective leadership, allowing Germantown to continuously improve its operations and keep everyone moving toward a common goal. The company’s core values—One Team, Humility, Reliability, Drive, and Continuous Improvement—are embedded in every facet of the business. “One Team” emphasizes unity, so that every employee works toward the same vision. “Humility” reflects a company-wide attitude of openness to feedback and growth, while “Reliability” guarantees that Germantown delivers on its promises to both employees and clients. “Drive” represents the passion for excellence that fuels the company’s progress, and “Continuous Improvement” pushes the team to innovate and refine their processes. By using EOS and focusing on these core values, Germantown creates a cohesive environment where each employee is empowered to contribute to the company’s mission of excellence and innovation.

While many companies in the steel fabrication industry have been slow to adopt new technologies, Germantown has embraced innovation. Armstrong and his team recognized the need to invest in automation and advanced technology to streamline operations and remain competitive. “We’ve really rolled up our sleeves to bring more and more automation in-house so that we can shrink our pipeline and speed up how quickly we process jobs through our shop,” Armstrong explains. This forward-thinking approach has allowed Germantown to drastically improve efficiencies and reduce project timelines—critical advantages in an industry where speed and precision are everything.

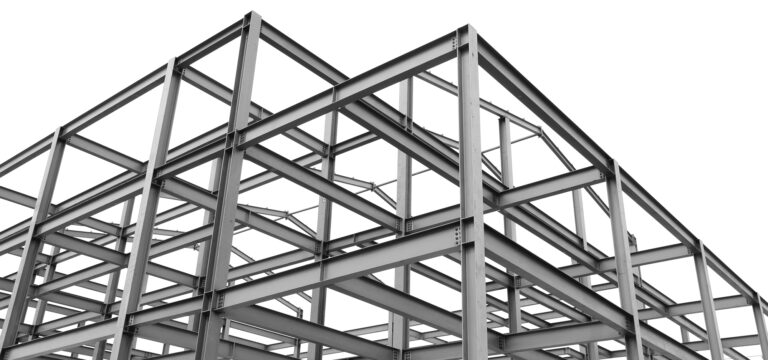

The company’s state-of-the-art facility in Jackson, WI, has become a showcase for cutting-edge technology. By investing in advanced tools like PythonX and Alltra plasma tables, Germantown has been able to automate much of the fabrication process, reducing the time and labor required to complete projects. The company has also started integrating robotics into its workflow, further enhancing precision and efficiencies.

Beyond robotics and machinery, Germantown continuously reviews the latest advances in software to optimize estimating, project management, and real-time reporting. This allows the company to provide clients with more accurate cost estimates and to monitor the progress of each job in real time, giving them a competitive edge.

Germantown’s commitment to automation and technology is not just about staying ahead; it’s about thriving in an industry experiencing profound change. According to Armstrong, there is very significant capital investment occurring in the steel industry with increasing demand for infrastructure that can support new technologies like electric vehicles. As the weight of these vehicles surpasses the capacity of older parking structures, the need for stronger, more durable construction fortified with steel is growing. By investing in advanced equipment, enhancing its workforce, and refining processes, Germantown Iron & Steel has positioned itself to capitalize on these changes. The company recognizes that as industries shift toward sustainability and electric vehicle adoption rises, the demand for steel infrastructure will only increase. This proactive approach ensures that Germantown remains not only relevant but poised to meet the future demands of the industry with efficiency and resilience.

Looking to the future, Germantown Iron & Steel’s vision is rooted in building a sustainable, impactful business while prioritizing its people, culture, and community. For David Armstrong, success isn’t measured solely by financial metrics, but by the company’s ability to grow its team, retain talent, and cultivate an environment where employees thrive, and customers keep coming back. “I’m not necessarily focused on ‘growth’,” says Armstrong. “Being the best at what we do, investing heavily in our team and our team culture, focusing on technology and automation; those are the metrics of success to me. If we do all those things, the natural byproduct is healthy growth.”

Armstrong sees opportunities for potential acquisitions, particularly with companies where aging owners may be looking to retire. With the new Germantown facility only utilizing half of its space, there’s also the potential to bring a proprietary product in-house, expanding its capabilities even further. While the company’s goal is to grow into a $100 million business within the next decade, Armstrong is clear that every opportunity will be thoroughly evaluated to ensure it aligns with the company’s long-term strategy. “What puts fire in my belly every day is that I have people who want to learn more. They want to think like owners that they want to see this place grow and they want to see their team be successful.”

The future of Germantown rests on deepening relationships with customers and continuing to invest in technology and automation. Armstrong has embraced his role as a visionary, recognizing that surrounding himself with the right people has been key to the company’s growth. With a strong team and streamlined processes, Germantown aims to position itself as the go-to iron and steel supplier across the Midwest, consistently delivering on promises and evolving alongside industry advancements.

Ultimately, Germantown’s future is focused on thoughtful, sustainable growth, driven by innovation and a commitment to creating opportunities for both its employees and the community. “I envision making sure we have the right people in place to seize the right opportunities as we grow,” says Armstrong. With the right team, a solid strategic foundation, and a willingness to adapt with an evolving industry, Germantown Iron & Steel is well-positioned to continue its ascent in iron and steel fabrication.