As anyone with experience will tell you, structure is one of the most important aspects in achieving success in business. It is that thing businesses strive for and once achieved, forms the literal backbone of an organization. It is the tangible and reliable cornerstone that those within a company look towards for support and balance. For Surespan Construction, the decision to create Surespan Structures was a simple one. Surespan Construction, itself a construction specialist that provides a world-class service across multiple disciplines from heavy civil construction through to the energy and industrial sectors, set up Surespan Structures, its off-site fabrication arm, in 1989.

Based on Vancouver Island, the group provides full spectrum precast concrete products and services for both concrete and steel deck bridges. In addition to this, the company produces architectural and structural concrete panels, earth and retaining walls, coping, road barriers, girders, pipe and pipeline weights and anchors, precast floats as well as utility vaults.

As with any organization, organic growth has been a consistent aspect to the success of Surespan Structures. When the company was founded over 33 years ago, the goal was to focus on precast concrete and steel decks for bridge construction. However, as Zoran Stanojevic, Director of Technical Sales at Surespan Structures explains, the expertise within the company led to a gradual growth to incorporate a multitude of services. “While the company started out in the precast and structural steel bridge deck market, it can now offer a wide range of services from architectural precast, insulated claddings, precast parkades, box beams and girders for the bridges to insulated panels or solid panels for the industrial buildings.”

Port Mann Bridge

With this experience and skill comes the ability to meet clients need, regardless of the project brief. The company excels with products ranging in size from small to large, including pre-cast barriers, vaults, and underground vaults for electrical services, while also providing bridge and building components for both industrial and commercial uses in warehouses and parkades. For any other company, there could be a temptation to rest on its laurels and continue producing these high-quality products alone, secure in its market position. However, at Surespan Structures they do things a little differently. For them, diversity is key and for Sheena Shaw, Executive Assistant at Surespan Structures, there are many facets to the service the company offers. “The majority of our work is the bridge structure components as well as building structure components. However, alongside this we also perform installations on some of the buildings we work on.”

This variety of services is something that truly sets the company apart. It is also a considerable factor in the ongoing growth that the company has experienced in recent years. According to Dave Nott, Business and Sales Manager at Surespan Structures, the precast side of the company has “diversified a lot over the years.” With an output that is currently almost triple what it was 10-15 years ago, it is clear to see that the company is doing something right. For Nott, it is this diversification that has led to the high rate of growth and the attraction and retention of talented skilled labour, technical and project management staff. “We have grown in quality, grown in quantity, [and] grown in the diversification of the different products that we use as well.”

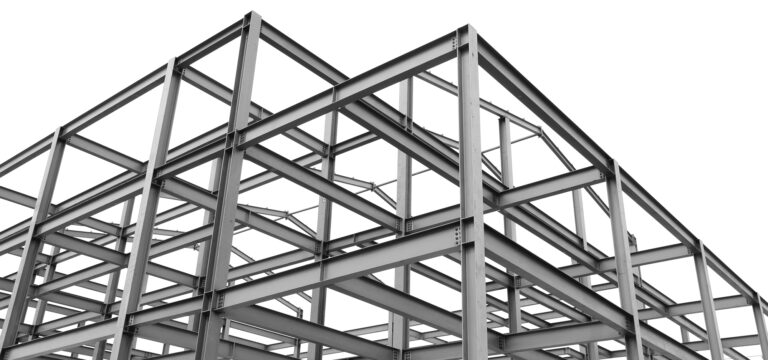

In addition to this, the company has also taken innovative approaches when it comes to the delivery and installation of these products. One key example of this is the company’s Accelerated Bridge Construction Method (ABC) where everything comes to the site precast manufactured, meaning the installation on site is faster. For Nott, this method is something that positions the company as an industry leader and has been a learning tool for the company. By using the experience gained through this approach, Surespan Structures can now apply this technique across multiple disciplines. “We have now taken the ABC method and applied it to parking structures, marinas, and wall panel jobs to mention a few. The benefit of this is that, instead of having your site occupied for months, Surespan can come in and put up the building in a week. Obviously, this is going to save a huge amount of time on site.”

“We have now taken the ABC method and applied it to parking structures, marinas, and wall panel jobs to mention a few.”

While the company is clearly on a positive trajectory, challenges will always need to be managed. The geographical location of the company can throw up issues in the form of transportation and shipping logistics. Simply put, the company is on an island, whereas most of the population and the projects that Surespan Structures will be working on, are on the mainland. For Nott, this challenge is simply something that needs to be overcome and by doing so, lends even further confidence in the company’s ability to complete a job to the highest level. “We have to do a lot of extraordinary stuff to overcome that geographical challenge and to win some of these jobs but when we do, we can compete almost anywhere.”

With an ever-growing portfolio, the list of high-quality projects that Surespan Structures work on are numerous. One groundbreaking example of this is when the company introduced insulated cladding to its product line. With improvements in technology, these panels now allow for more efficient weather performance and significantly improved insulation in the panels, something which Surespan is delighted to offer its customers. Ponderosa Commons in the University of British Columbia was completed in 2013 and is one of the company’s stand-out projects, receiving the Canadian Society of Landscape Architects 2018 National Medium-Scale Award. Surespan Structures designed, supplied, and installed the precast concrete insulated system –for the first time in the company’s history—for two new seventeen-story student accommodation buildings at the university. One building consisted of 1,465 precast panels, while the other used 998 and included the use of colored concrete. During the project, the company rectified a two-month delay and assisted in the completion of the second building eight months ahead of schedule.

While Surespan Structures may be located on Vancouver Island, that does not stop the company from working right across the country with bridges being supplied in Alberta, Manitoba, Ontario & Quebec, as well as into the US. The company’s ability to deliver the highest quality on its projects has earned it a reputation envied by its competitors. This reputation is well earned. Within BC, the company has produced bridges and buildings across the province. The company worked on the Kelowna Memorial Parkade in 2016, which is one of four parkades they have completed in Kelowna. They have also produced multiple high-profile jobs in the Vancouver area including the supply and install of the Habitat Skirt, an artificial shoreline skirting three sides of the Vancouver Convention Centre. This project received the CPCI’s Project of the Month in May 2019, and as Stanojevic explains, it demonstrated an ability to meet both demanding and unique requirements. The Habitat Skirt was installed from the water, with the 80,000lb pieces being installed using a crane on a large barge. The project consists of an underwater staircase-shaped precast in the tidal zone. What really makes this job stand out is the additional details that went into it both from a scientific and sustainability standpoint. It was designed with recesses in the precast panels allowing for sea life to live in them, creating miniature tidepools. The idea behind the project was that every time the tide came in, barnacles would be left behind to grow. According to Nott, the project had a positive impact on many levels. He explains that soon after the project was completed, a report was released which stated that sea life was already present in and around the structure and, given that it can take a number of years for animal life to return to an area post construction, this was an unequivocal success.

Kelowna Memorial Parkade

Habitat Skirt

While all this points to the level of expertise in-house at Surespan, you might think that it is happy with its success today. Unsurprisingly however, the company has no intention of resting on its laurels. In an example of the quality the company produces, we only have to look to the number of times it has been awarded for its work. Surespan won the 2019 Gold Award of Excellence presented by the Vancouver Regional Construction Association for their work producing the Simon Fraser University’s SE3P Building Architectural White Precast Cladding Panels. Surespan supplied & installed 736 pieces featuring curvilinear white textured prestress concrete made using custom form liners, imported aggregate and cement powder. This work, rightly awarded, is testament to the quality the company provides.

The company’s largest project to date was the precast deck for the Port Mann Bridge. As the largest bridge in Vancouver the project proved to be a testing one which, with over 1200 panels, took over a year of casting. Nott explains that the level of skill required to complete the job meant that Surespan Structures had to bring its best to the job, every day. “The job consisted of fairly complex panels. It was a shape we hadn’t really dealt with before with fancy formwork. Having said that, it was another very successful project because it allowed us to demonstrate our ability to complete large scale mass production of high-quality precast which is something we excel at.”

Going forward, the outlook for Surespan Structures remains positive, with the company focused fully on continuing its growth and expansion. While Stanojevic acknowledges that the company experiences the same challenges as anyone else in the market, he feels that, with its high-quality products and innovative processes, the company is in excellent shape to move forward with confidence. “We have the same challenges as everyone else. There are always challenges with labor shortages and rising prices, but I think this is a problem which everybody has. At Surespan Structures, we prefer to focus on the positives. We are fully booked, and we are working at the top of our capacity.” As they say in the business, if you ever want success, structure is vital.