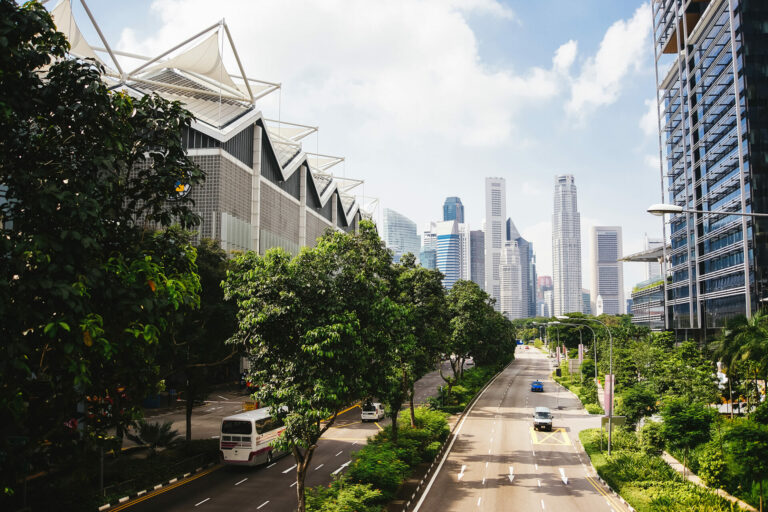

Cities are sinking. As catastrophic and alarming as this thought is, it is not necessarily something that is new to scientists and engineers. In fact, when we consider that Venice, the most famous of these sinking cities has navigated this issue through an inventive and lucrative tourist industry, we can take a step back and view it for what it really is. In general terms, Subsidence is the downward vertical movement of the Earth’s surface. Caused by both natural and human activities, it is a common and well-known geological feature that is a natural, and perfectly normal part of house building. Research has long been studying the effects of subsidence on large-scale built-up areas such as cities. It stands to reason that, with skylines expanding continuously, the effects on the surface below may also be changing.

The results of these studies are complex, however. Various factors play a part in determining the effects that the built environment can have on a piece of land. From underlying soil type and the buildings foundation modes to natural topography and location, many cities could be finding themselves in precarious situations. The US Geological Survey and the Graduate School of Oceanography at the University of Rhode Island has recently conducted a study on the effects of building in New York City. In the first piece of research that specifically looks into the contribution of the built environment on subsidence, researchers noted that NYC is sinking at a rate of 1-4 millimeters per year. While this is in line with regional rates, it discovered that some areas fell far outside these acceptable levels. In fact, researchers calculated the mass of all buildings in the city and discovered that, depending on the soil type of a particular area, some buildings have the potential to sink over 600 millimeters. The findings of this paper, titled: The Weight of New York City: Possible Contributions to Subsidence From Anthropogenic Sources, suggest that the risk of large-scale buildings on flood risk is actually quite a significant one. Researchers also stated that, due to the escalation in storm intensity over recent years coupled with the rise of sea levels, coastal cities such as New York City are at risk. “As coastal cities grow globally, the combination of construction densification and sea level rise imply increasing inundation hazard. The point of the paper is to raise awareness that every additional high-rise building constructed at coastal, river, or lakefront settings could contribute to future flood risk, and that mitigation strategies may need to be included.”

Editorial credit: George Wirt / Shutterstock.com

These views are echoed by a recent Intergovernmental Panel on Climate Change (IPCC) report which found that the rate and focus of “climate sensitive planning” is far slower and effective than it needs to be. “Many cities and settlements have developed adaptation plans, but few have been implemented so that urban adaptation gaps exist in all world regions. Exposure to climate-driven impacts… in combination with rapid urbanization and lack of climate sensitive planning, is affecting marginalized urban populations and key infrastructure.” When we look at the situation globally, the stark nature of these challenges come sharply into focus. Jakarta, the capital city of Indonesia has the unwanted accolade of being the fastest sinking city in the world. Astonishingly, the city is dropping by around 30 centimeters per year. With much of the city sitting below a rapidly rising sea level, flooding is common, and it is estimated that in much of the city will be uninhabitable by the end of the decade.

So, what can be done to mitigate against these challenging conditions? Given that the current proposal from the Indonesian government is to relocate the capital to an under-construction city 800 miles north of Jakarta, it seems viable solutions need to be found quickly. According to the IPCC report, the most necessary changes that need to take place revolve around carbon emissions. While these widely accepted yet challenging targets are the best way of solving the crisis, alternatives are necessary. Pervious pavements and underground tunnel systems to absorb stormwater need to be developed in cities while grey infrastructure and retrofitting should be prioritized. The report suggested the widespread introduction of elevated houses which stood on stilts, but it was something else that truly grabbed the headlines.

Amphibious architecture is the process of designing buildings that work with water, rather than against it.

Amphibious architecture is the process of designing buildings that work with water, rather than against it. Rather than adopting traditional building methods, amphibious structures are not fixed and, as the tide rises around them, so to do the buildings themselves in a way that is comparable to a boat. For Elizabeth English, Associate Professor at the University of Waterloo and organizer of the International Conference on Amphibious Architecture, Design and Engineering that took place in Ontario recently, it is a case of acceptance. “With amphibious construction, water becomes your friend. The water gets to do what the water wants to do. It’s not a confrontation with Mother Nature—it’s an acceptance of Mother Nature.” While starting her career studying the effects of wind and hurricanes, English pivoted to the effects of water on the built environment having seen the effect of Hurricane Katrina. “Katrina was much more a water event than a wind event. I started looking at the implications of all the flood damage and the social disruption that it caused, and I became very, very angry about the cultural insensitivity of the solutions that were being proposed.” These insensitivities consisted of recommendations to permanently elevate homes which, for English, would have destroyed any remaining element of community to an already devastated region.

Taking her lead from the Netherlands, a country that has historically had to think creatively about flood mitigation, English discovered amphibious homes. While she felt that it had potential, it was not a suitable solution for the low-income communities that were most likely to be negatively impacted. English founded the Buoyant Foundation Project, a community initiative that designed, tested, and retrofitted amphibious foundations in New Orleans. By using a system that attached a steel frame to the underside of the house along with foam buoyancy blocks, the house would rise and hover above the tide when surrounded by water. For English, the project was an enormous success. The foundation had a system that, while not necessarily perfect, was simple, effective, and cheap. Incredibly, things did not stop there either. To date, the Buoyant Foundation Project have designed amphibious housing for low-income areas such as Nicaragua and Jamaica while designs have recently been used to build a bespoke residential home on the Thames River in London.

In the context of rising sea levels and increasingly disastrous weather events, the need to protect against flooding has never been more necessary. As cities such as Jakarta and New York City sink underwater, feats of engineering are needed now more than ever. Sadly however, the greatest level of need comes from those communities who can ill afford it. For English and her colleagues at the Buoyant Foundation Project, the goal is not on solving the world’s problems, it is about providing equity. The Buoyant Foundation Project focuses on retrofitting as a less expensive and more sustainable way to increase the resilience of existing communities located in flood-prone regions. Retrofitting existing buildings produces less demolition waste and requires fewer new materials compared to building entirely new buildings.”